Where as in case of Gauges these are the Fixed dimensions instruments.In most cases , these doesn't have adjustable member for measuring varying dimensions of lengths and angles.

Lets discuss about some Measuring Instruments and Gauges:

1.Vernier Caliper:-

Vernier Caliper is an instrument which is used to measure to external as well as internal dimensions of an objects like shafts,thickness of any objects,depths of holes and slots.A Vernier scale on caliper may have a least count of 0.02 mm while a micrometre have least count of 0.001 mm.

Vernier Caliper is an instrument which is used to measure to external as well as internal dimensions of an objects like shafts,thickness of any objects,depths of holes and slots.A Vernier scale on caliper may have a least count of 0.02 mm while a micrometre have least count of 0.001 mm.As its name says that it is mainly used to measure the heights of parts to an accuracy of 0.02mm.

3.Vernier Depth Gauge:

The vernier Depth Gauges are used to measure the depth of the holes,recesses, and distance from plane surface to a projection, to an accuracy of 0.02mm.

The Ring Gauges are mainly used to check or measure the diameter of shafts or studs.

5.Plug Gauges:

5.Plug Gauges:

The Plug Gauges are used to check the accuracy of hole.In engineering sectors like manufacturing companies,tool rooms,workshops the Standard Plug Gauges very important Instruments. The limit plug gauge is used where the large quantities are produced. The single -ended plug gauges limit plug gauges has separate Go & No Go members.The progressive limit plug gauges has Go&No Go members on the same side of a handle.

6.Snap Gauges:

7.Slip Gauges:

Slip Gauges are also know as Gauge Blocks.Gauge blocks come in sets of blocks with a range of standard lengths.These are generally used to check or measuring the linear dimensions very accurately.

The Feeler Gauges are used to check the clearances between the two mating surfaces.

Inside Micrometers are generally used to measure the large internal diameter about 50mm with an accuracy of 0.01mm.

10.Outside Micrometer:

It is used to measure the outside of an objects diameter or length of a small parts with an accuracy of 0.01mm.

It is used to measure the outside of an objects diameter or length of a small parts with an accuracy of 0.01mm.It is used to measure the pitch diameter of screw threads with an accuracy of 0.01mm

12.Depth Gauge Micrometer:

Depth Gauge Micrometers are used to measure the depth of holes, slots and recessed areas with an accuracy of 0.01mm.

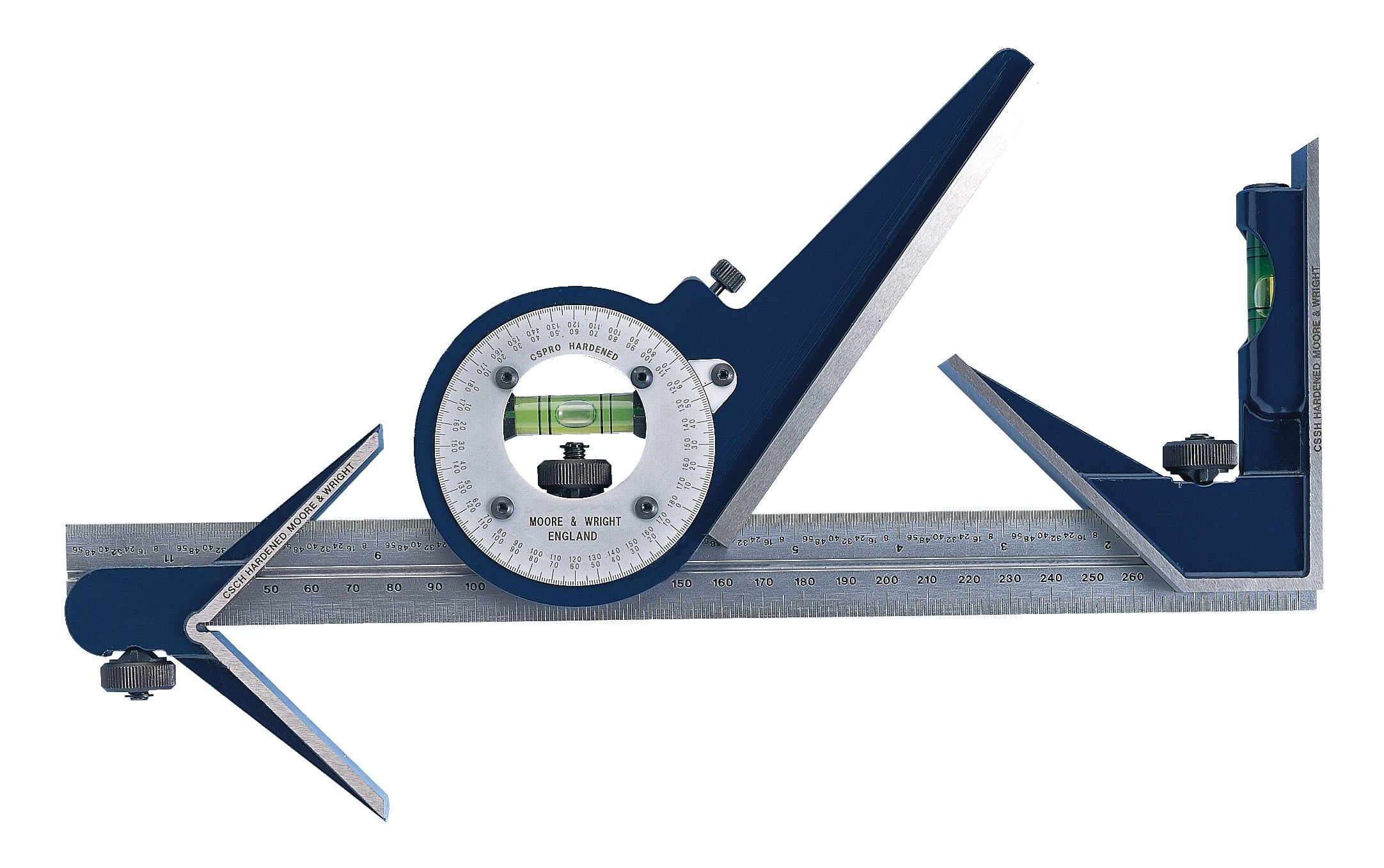

The Combination set is an very important instrument and has all the essential features of try square ,bevel protractor,rule and scriber.

The Universal Bevel Protractors are the instruments which are used to measure the angles with the limits of 5minutes(1/12 of a degree).These are also called as Vernier Bevel Protractors.

These are used either to measure angles more precisely than bevel protractors or for locating any work to a given angle within very close limits.

16. Scribing Block:

The Scribing Blocks are used to locate the centers of round bars.

17.Surface Plate's:

Surface plate's which are used to check the trueness of Flat Surface.

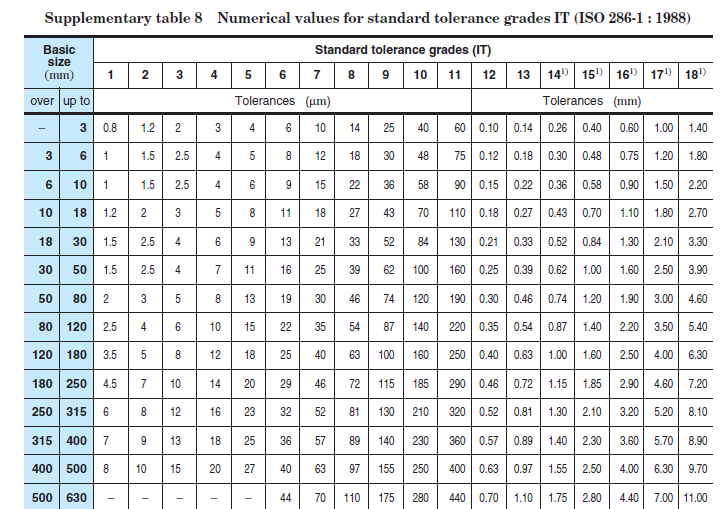

18.Tolerance:

Its is defined as the difference between the Upper Limit and Lower Limit of a dimensions.

0 Comments