Pipework is extensively used throughout an offshore installation to move fluids and gases from one location to another. Usually large diameter pipelines as used to carry the production products from installation to installation or from the field to the onshore terminal.

Pumps and compressors are used to drive fluids and gases along pipes and valves to route and control the various substances and ensure that they are correctly segregated from each other. The contents of the pipework are carried at widely varying temperatures, pressures and flow rates and,therefore, different types of pipework and associated equipment are required.

Pumps and compressors are used to drive fluids and gases along pipes and valves to route and control the various substances and ensure that they are correctly segregated from each other. The contents of the pipework are carried at widely varying temperatures, pressures and flow rates and,therefore, different types of pipework and associated equipment are required.

There are three common methods of joining piping, each with its own advantages and disadvantages.

- Butt Welded Piping Systems

- Screwed Piping Systems.

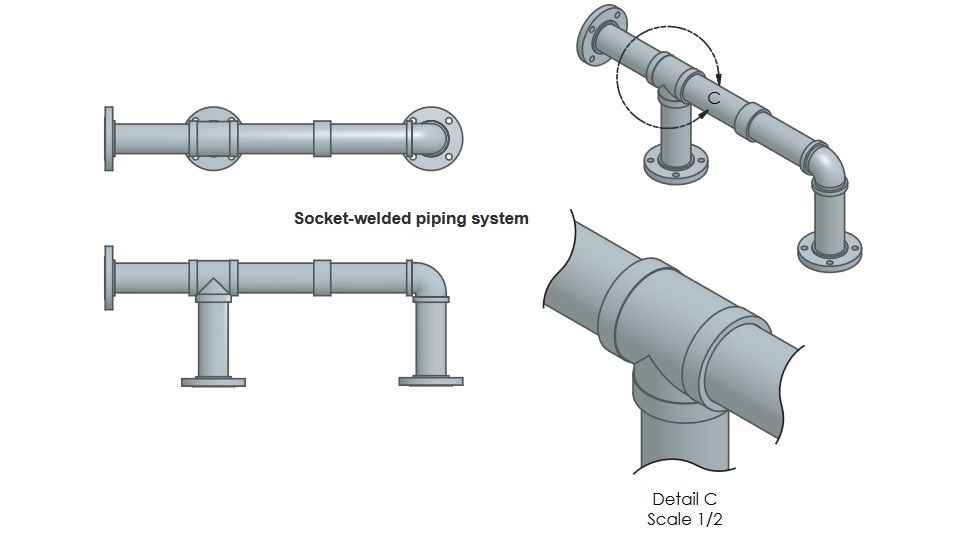

- Socket-Welded Piping Systems

Butt Welded Piping Systems are used for most process, utility or service piping. Butt welding is the most practicable way of obtaining strong, leak-proof joints; especially on larger piping. The pipe and fitting used have, or are prepared with, standard weld preparation. They require high levels of workmanship in their assembly and welding.

Socket-Welded Piping Systems are used for lines of small diameter which carry flammable, toxic or expensive materials where no leakage is permitted. They are easier to assemble and weld than butt welds and no weld metal can enter the bore. The pipe end is finished square and fitted into the fittings, usually with a 1.5 mm gap. This gap sometimes pockets liquids and is not recommended if severe erosion of crevice corrosion is anticipated

-page-001.jpg)

0 Comments